This

page illustrates the process for making a large architectural cornice

molding in the traditional manner using hand planes.

Due

to some long term water leakage, a portion of the cornice molding on

the original Westford Academy building (1794), now the Westford

Museum,

had suffered significant damage. Below is an image of that

corner,

including a newly exposed bird's nest, as it appeared after the

rotted cornice was removed. The cornice was

not an original 18th century molding, but rather material that was

added

during the building's restoration in the late 1970's and early '80's.

In any case, it needed to be replaced with a matching molding, and

rather than search for a replacement, or have a custom cutter

produced for use in a modern molding machine, I offered to

make a

new 8' section using handplanes.

In

the 18th and a good portion of the 19th century, cornice moldings such

as

these were often made using a combination of hollows and rounds,

and rabbet planes.

For example, the cornice shown above would typically require

two

pairs of hollows and rounds, a rabbet plane, and a couple of

bench planes -- seven different

planes. Alternatively, dedicated cornice planes such as the

one

shown to the right were developed in the 18th century. What

this

plane provides in terms of simplicity, requiring a single plane, is

countered with the need for significant brute force. Given

the

incredibly wide

cutting profile, this plane required two fairly strong men to operate,

one pushing, and the other pulling a rope attached to the

crossbar.

Since

I don't own a large, dedicated cornice plane that matches the existing

profile, what follows is a description of the steps taken to create a

replacement molding using several hand planes. Using

this

method, along with a comprehensive set of hollows and rounds, one can

reproduce essentially any molding.

The

starting material was a piece of rough sawn, air dried 2x10 pine.

The piece was planed flat and cut to width prior to tracing

the

old molding profile on both ends. The edges were jointed

straight using a large jointer plane.

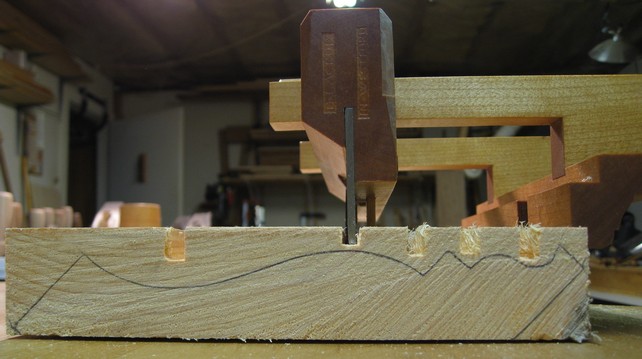

Below,

a plow plane is used to produce grooves coincident with the inflection

points of the profile. These will serve to guide the

subsequent

planes and provide help in judging the profile depth along the

entire length of the board. Using a wider iron also helps to

quickly remove excess material.

At

this point I realized that I should have planed the board down some

more before starting, so I simply used a scrub plane to hog away more

of the surface.

Below,

the work of the #18 round plane is nearly complete.

The

profile with the first section complete:

And

here's the profile after using the #18 hollow plane, a rabbet, and a

smaller hollow and round pair. One of the hollow planes is

shown

on it's resulting profile.

And

finally, after beveling the profile edges the cornice molding is

complete:

The

completed molding next to a small section of the original:

Removing

all of that material results in a bit of waste. The beauty of

hand planes, however, is that the waste doesn't end up in the form of

dust, and potentially in your lungs. Here's just one of the

piles:

The

final product on the Museum following installation and painting: